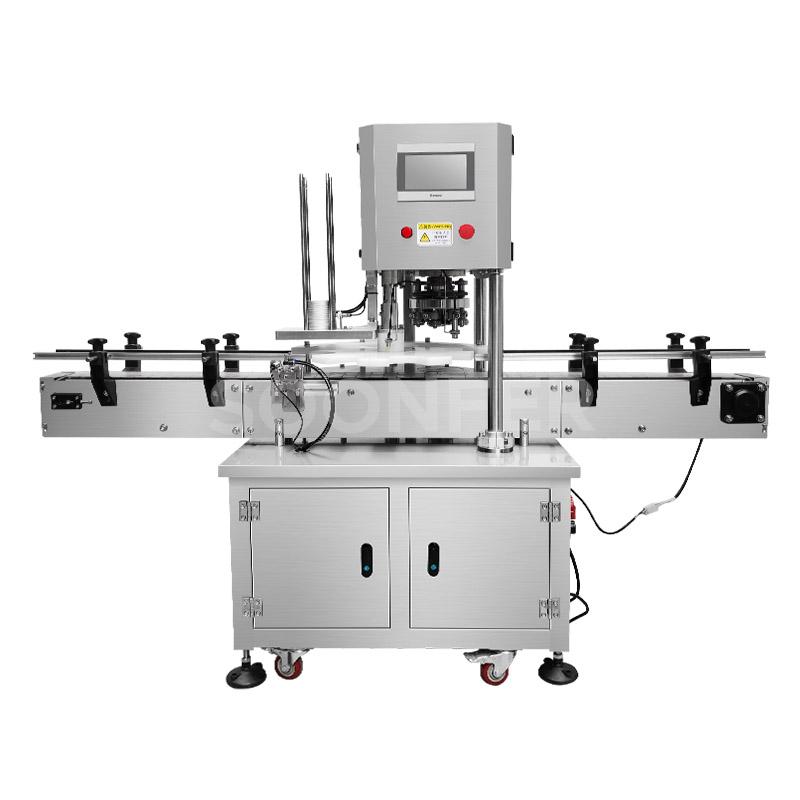

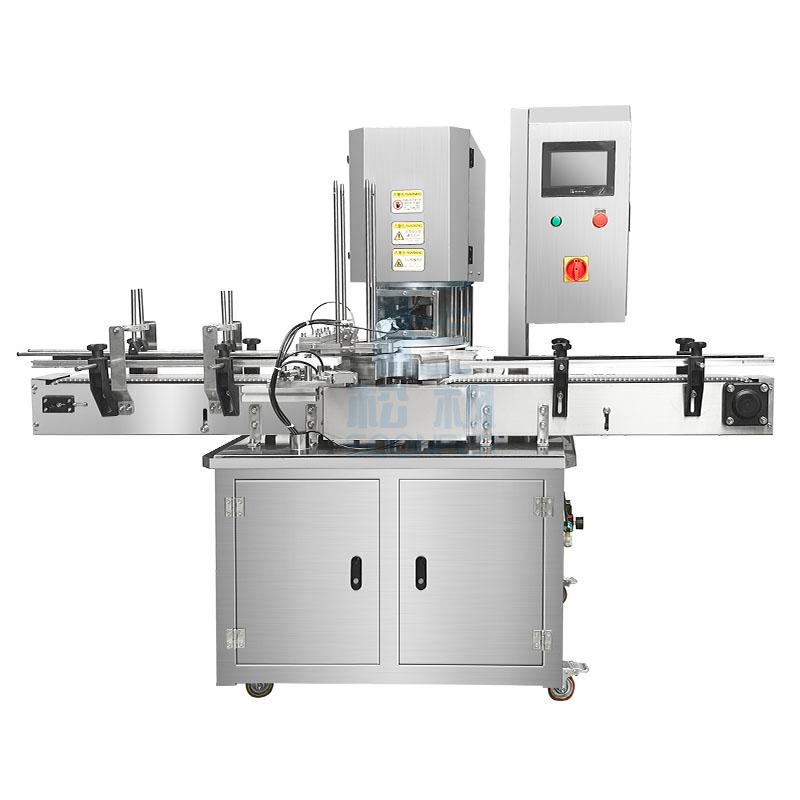

Automatic Vacuum Nitrogen Filling Metal Goat Milk Powder Metal Tin Can Sealer Machine

Automatic vacuum can sealing machine

The automatic vacuum can sealing machine is suitable for packaging various round-mouth tinplate cans, aluminum cans, and plastic cans. First vacuum, then fill with nitrogen, and finally seal, effectively extending the shelf life of the product, which is very suitable for milk powder production companies.

Specification of vacuum can sealing machine

| Model No. | SF-G2S |

| Sealing Head Number |

1 |

|

Seaming Rollers Number |

2 |

| Sealling Speed | 5-8 cans/min (Depends on can size) |

|

Sealing Height |

50-200mm |

|

Sealing Can Diameter |

φ73-127mm |

| Air Source Pressure | 0.6-0.8Mpa |

|

Machine Size |

2000(L)* 850(W)* 1800(H)mm |

| Machine Weight |

700kg |

| Power |

220V, 50/60HZ, 3kw |

Features of vacuum can sealing machine

1. The machine can automatically complete a series of processes such as can feeding, cap placement, vacuuming, nitrogen filling, and sealing.

2. Siemens PLC control system makes the machine operate more stably and work more efficiently.

3. The seals of the vacuum system use vacuum-specific fluorine rubber sealing rings, which are resistant to high temperatures and prevent leakage.

4. The seaming rollers and chuck are processed by Cr12 die steel, which is durable and high tightness.

5. The residual oxygen content is less than 3%, effectively extending the shelf life of the product and improving product quality.

Call Us : +8615627212086

Call Us : +8615627212086 Email : info@soonfermachinery.com

Email : info@soonfermachinery.com