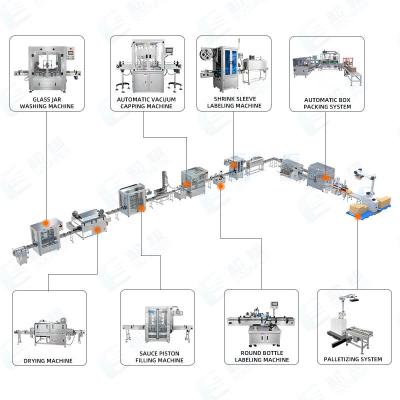

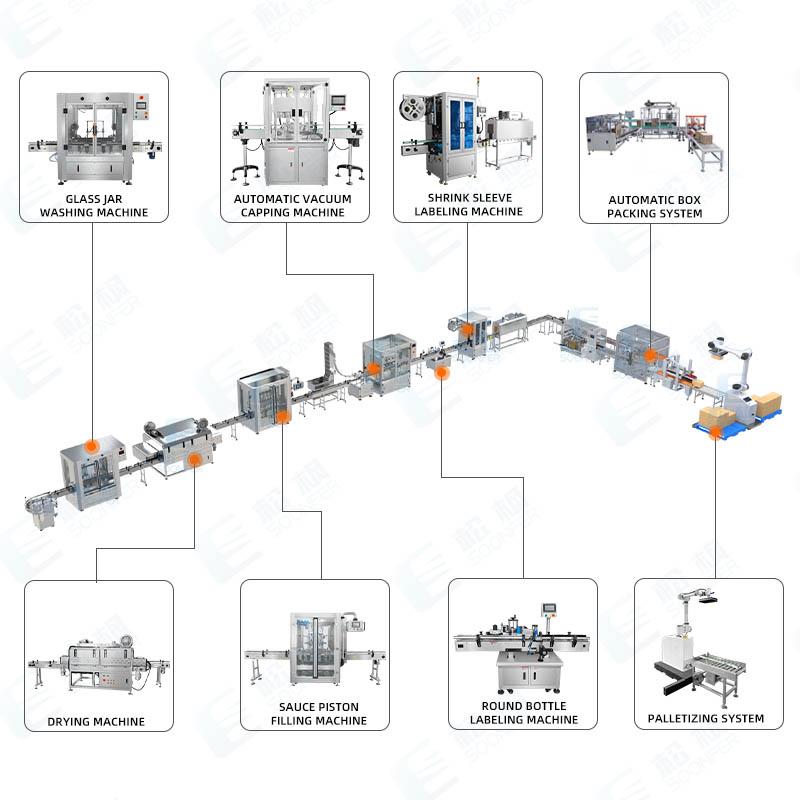

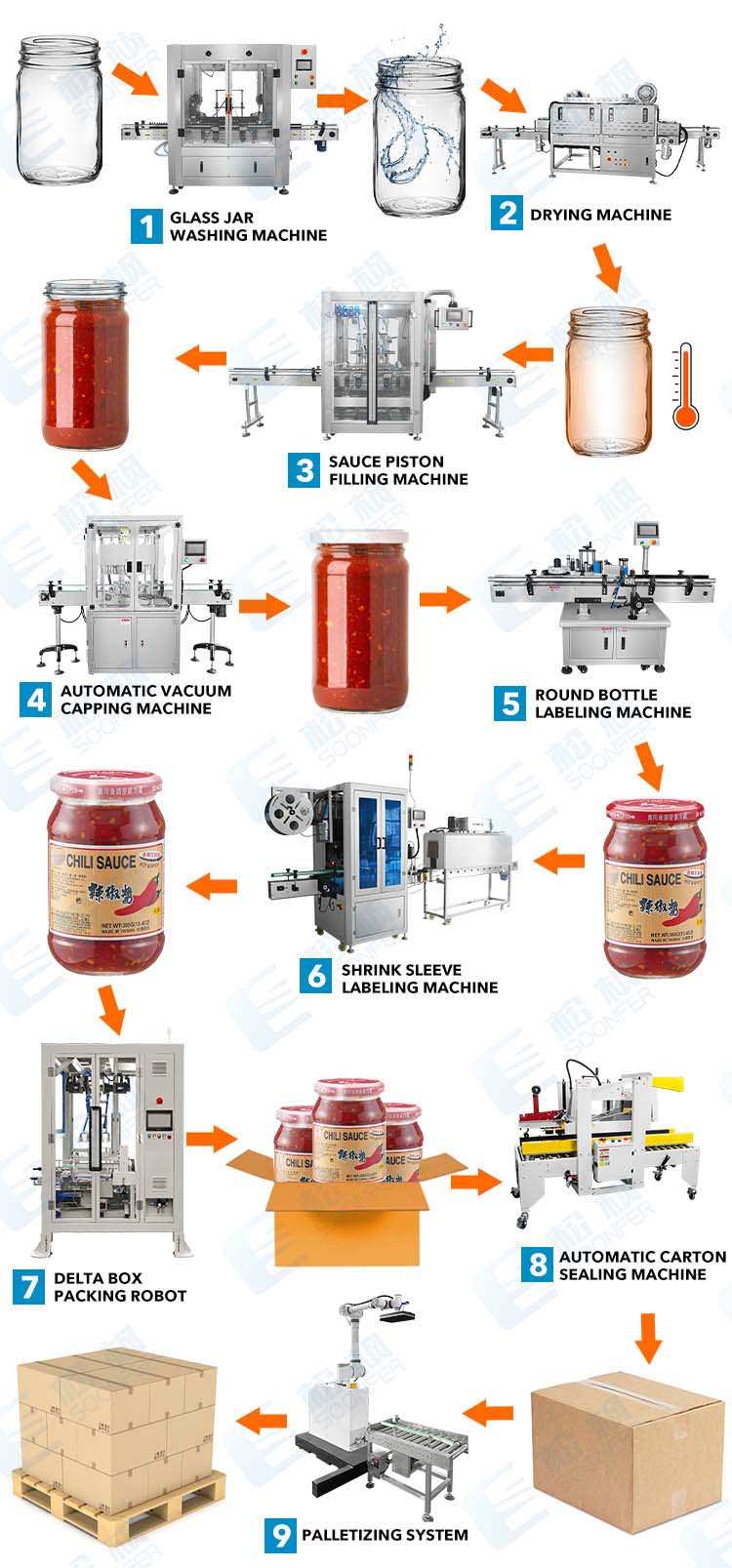

Automatic Piston Tomato Paste Chili Sauce Glass Bottle Filling Vacuum Cappping Labeling Corrugated Cartoning Machine Line

Application of sauce bottle filling packing machine line

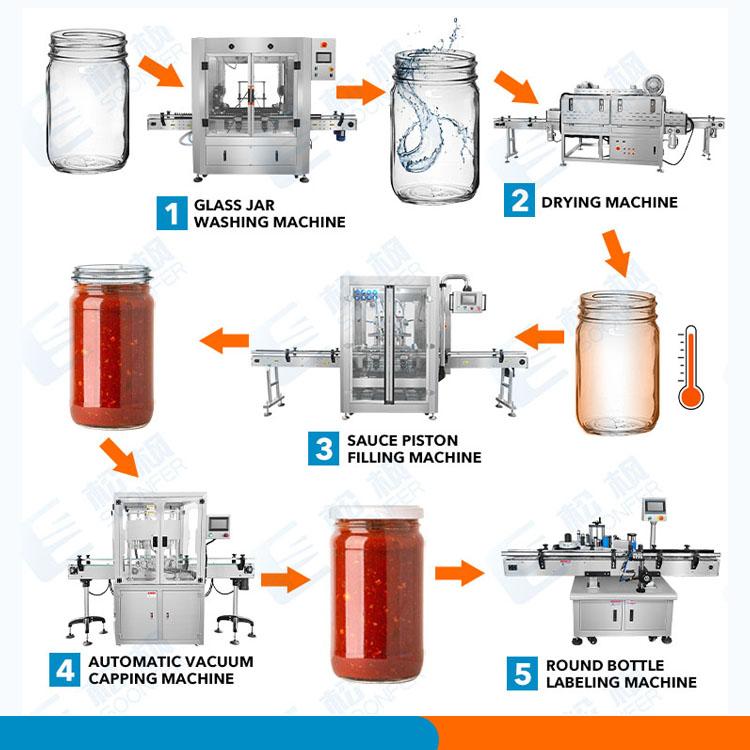

The automatic piston pump sauce filling and packaging line is engineered specifically for glass bottles, providing a smooth and hygienic workflow from bottle preparation to final pallet output. The line begins with a semi-automatic rotary bottle unscrambler and continues through bottle washing and hot-air drying to ensure each container is clean and ready for filling. The piston filling machine delivers precise dosing for thick sauces, by a vacuum capping system that ensures secure, airtight sealing. After capping, bottles move through both round-bottle labeling and sleeve labeling stations to achieve a professional, retail-ready appearance. Finally, automatic cartoning, case sealing, and palletizing complete the line, enabling efficient large-scale production with stable and consistent performance.

Features of sauce bottle filling packing machine line

1.Complete glass bottle filling and packing workflow from unscrambling, washing, drying, filling, and capping to final palletizing.

2.High-precision piston filling designed for viscous sauces, pastes, and similar products.

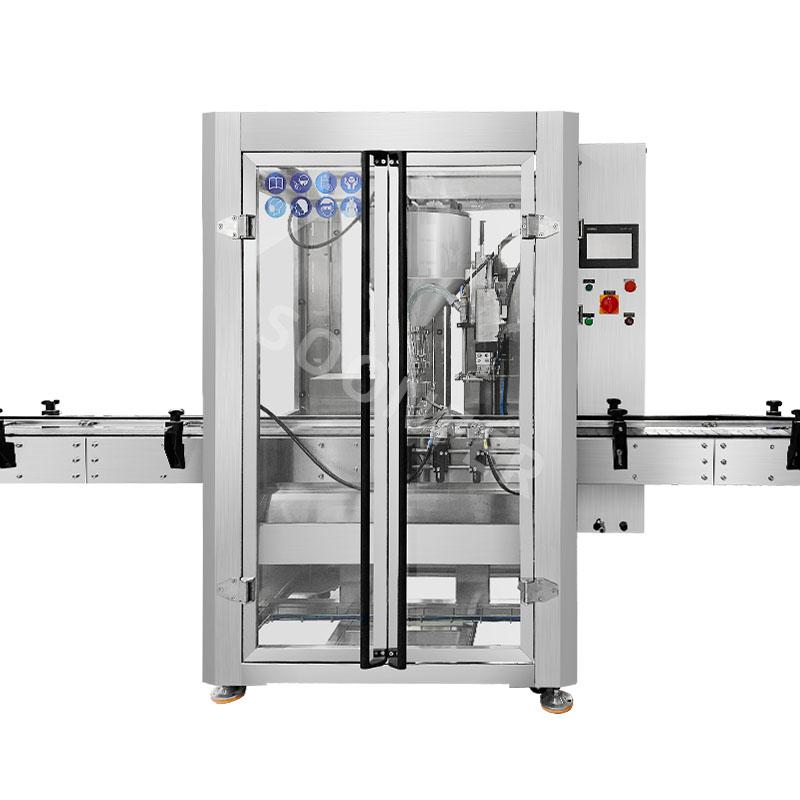

3.Vacuum capping system ensures strong sealing integrity and improved product freshness.

4.Dedicated round-bottle labeling and sleeve labeling steps for premium, multi-stage packaging presentation.

5.Reliable bottle washing and drying units enhance hygiene and reduce contamination risks.

6.Automated cartoning and case sealing improve production speed and reduce manual labor.

7.Stable palletizing system creates orderly stacks and facilitates downstream logistics.

8.Centralized PLC control with intuitive operation, easy maintenance, and consistent line coordination.

Call Us : +8615627212086

Call Us : +8615627212086 Email : info@soonfermachinery.com

Email : info@soonfermachinery.com